Basic Info.

Model NO.

Nylon lockout hasp

Shackle Diameter

6mm

Shackle Length

25mm

Color

Red or Customize

Key System

Keyed Differ, Keyed Alike, Master Key, Grand Maste

OEM

Offered

Transport Package

Inner Boxply-Wooden Box

Specification

01-08

Trademark

SOIEA

Origin

China

HS Code

8301400000

Production Capacity

6000000

Product Description

Description

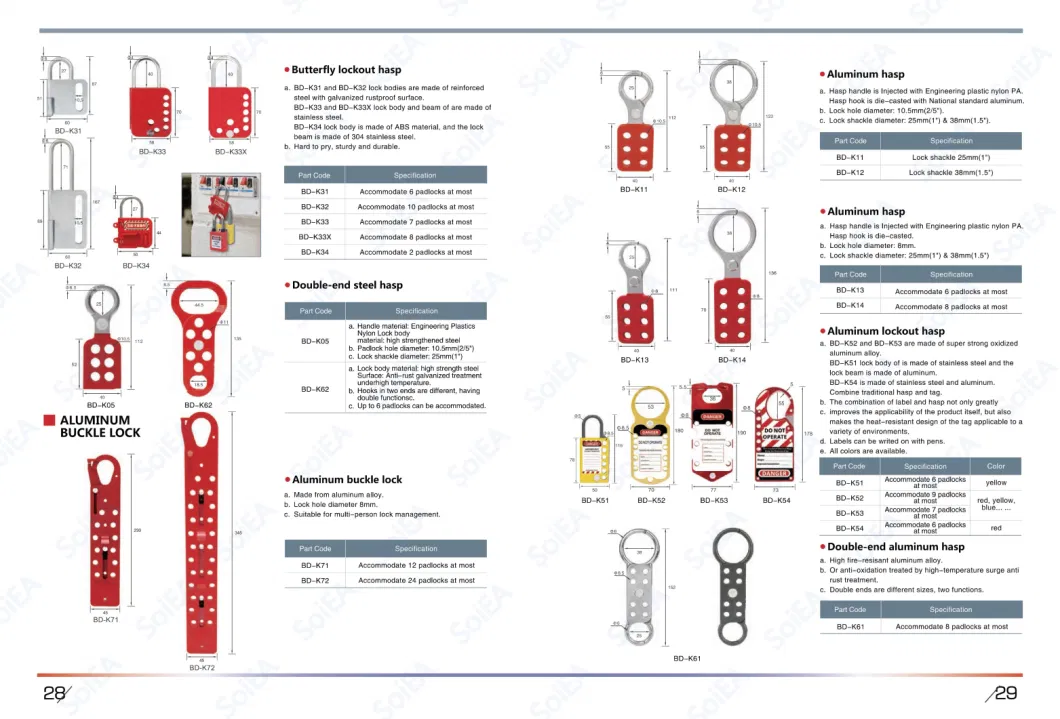

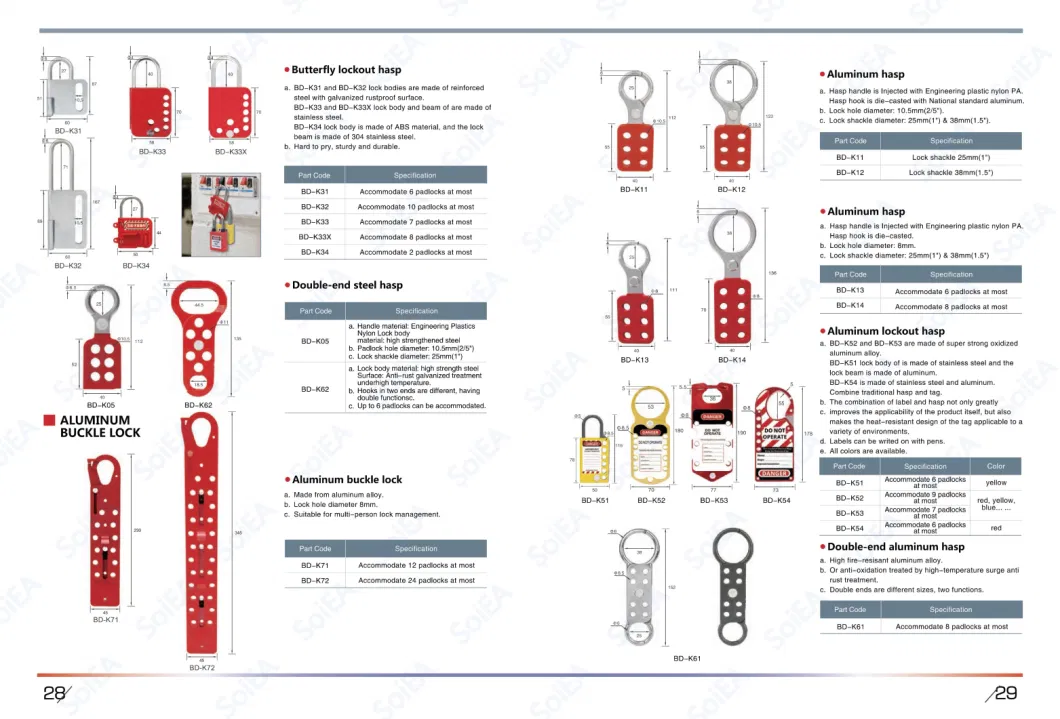

Pa coated steel hasp

1.Made from Engineering plastic nylon PA injection molding, galvanized rustproof surface.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm (1.5").

4. Such as custom made stainless material, themodel behind plus"S".

Economic steel hasp

1. Made from steel materials, high temperature sprayplastics and rust treatment.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5")

Steel hasp with hook

1. Made from Engineering plastic nylon PA injectionmolding,galvanized rustproof surface.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5").

4. Hooks are provided to avoid self-opening of hasps

Economic steel hasp with hook

1. Made from durable steel, high temperature spray plasticand rust treatment.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5")

4. Hooks are provided to avoid self-opening of hasps.

Aluminum hasp

1. Hasp handle is Injected with Engineering plastic nylon PA

Hasp hook is die-casted with National standard aluminum.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5").

#1 What is LOTO? (Lock out / Tag out = LOTO)

When the equipment or tool is being repaired, maintained or cleaned, the power source related to the equipment neeocut off, so that the equipment cannot be started, and all energy sources (power supply, hydraulic source, air source, etc,are turned off.

· Lock out: Lockout is using the safety and other equipment to lock the machine to isolate from unauthorized operationsand ensuring each worker's safety until the work is finished. · Tag out: Tagout is usingfor warning the people that the energy source or equipment is locked that can not operateoptionally.

· Disconnecting means: One piece or one group equipment can disconnect the energy source or the power supply circuit.

· LOTO: In order to ensure that the equipment energy is turned off , the equipment is kept in a safe state. Prevent accidental injury to the staff or related person inside or next to the equipment caused by the equipment being accidentally operated.

#2 Why should use LOTO?

LOTO is in order to prevent the workers from the danger that caused by the machine start accidentally, the equipmentaunch abnormal. the eneroy source release when the worker want to repair or maintain it, So that it can keep the workersoersonal security. The Key of LOTO is cut off the connection between machine and power source, Jock on the source.release residual power.

#3 When & Where should use LOTO?

· Daily maintenance, adjustment, cleaning, inspection and commissioning for equipment. Enter into the limited space, hotwork, dismantling work and so on in the tower, tank, electrified body, ketle, heat exchanger, pumps and other facilities.

· Operation involving high voltage. ( including the operation under the high-tension cable )

· Operation require closing the safety system temporary.

· Operation during maintenance and commissioning of non-processing.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Pa coated steel hasp

1.Made from Engineering plastic nylon PA injection molding, galvanized rustproof surface.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm (1.5").

4. Such as custom made stainless material, themodel behind plus"S".

Economic steel hasp

1. Made from steel materials, high temperature sprayplastics and rust treatment.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5")

Steel hasp with hook

1. Made from Engineering plastic nylon PA injectionmolding,galvanized rustproof surface.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5").

4. Hooks are provided to avoid self-opening of hasps

Economic steel hasp with hook

1. Made from durable steel, high temperature spray plasticand rust treatment.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5")

4. Hooks are provided to avoid self-opening of hasps.

Aluminum hasp

1. Hasp handle is Injected with Engineering plastic nylon PA

Hasp hook is die-casted with National standard aluminum.

2. Lock hole diameter: 10.5mm(2/5").

3. Lock shackle diameter: 25mm(1") & 38mm(1.5").

#1 What is LOTO? (Lock out / Tag out = LOTO)

When the equipment or tool is being repaired, maintained or cleaned, the power source related to the equipment neeocut off, so that the equipment cannot be started, and all energy sources (power supply, hydraulic source, air source, etc,are turned off.

· Lock out: Lockout is using the safety and other equipment to lock the machine to isolate from unauthorized operationsand ensuring each worker's safety until the work is finished. · Tag out: Tagout is usingfor warning the people that the energy source or equipment is locked that can not operateoptionally.

· Disconnecting means: One piece or one group equipment can disconnect the energy source or the power supply circuit.

· LOTO: In order to ensure that the equipment energy is turned off , the equipment is kept in a safe state. Prevent accidental injury to the staff or related person inside or next to the equipment caused by the equipment being accidentally operated.

#2 Why should use LOTO?

LOTO is in order to prevent the workers from the danger that caused by the machine start accidentally, the equipmentaunch abnormal. the eneroy source release when the worker want to repair or maintain it, So that it can keep the workersoersonal security. The Key of LOTO is cut off the connection between machine and power source, Jock on the source.release residual power.

#3 When & Where should use LOTO?

· Daily maintenance, adjustment, cleaning, inspection and commissioning for equipment. Enter into the limited space, hotwork, dismantling work and so on in the tower, tank, electrified body, ketle, heat exchanger, pumps and other facilities.

· Operation involving high voltage. ( including the operation under the high-tension cable )

· Operation require closing the safety system temporary.

· Operation during maintenance and commissioning of non-processing.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------